Get the best out of you ”

Are you planning to invest in industrial screen printing machines?

Sometimes, the decision to buy right screen printing machine for industrial application can be tedious. Isn’t it? Modern screen printing shops rely on industrial machinery to function. It is important to choose the right machinery customized to your needs while keeping budget in mind.

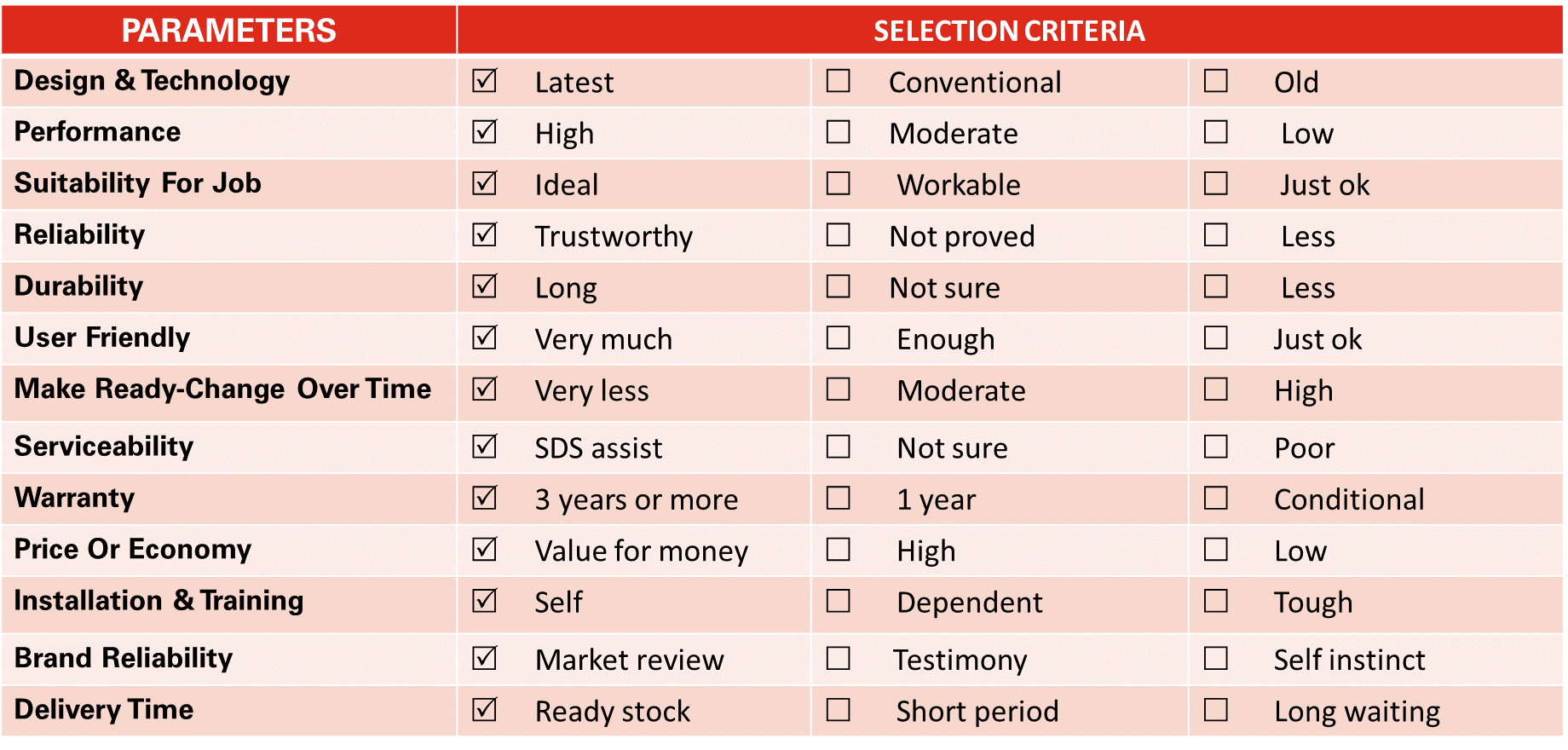

Here are 13 parameters you should consider before buying and maintaining screen printing machinery:

All the parameters have their own importance and when you are making long term decision on investment in assets like industrial screen printing machines, it becomes utmost importance to take the right decision.

Eight criteria to consider:

The initial cost vs quality

When shopping on a budget, many companies focus on the initial price, but often it’s the cost in the long run that is worth considering. More expensive high-end machinery is often built to last, so you’ll spend less in longer run on repairs. Such screen printing machinery may also have greater precision, helping to minimize rejections. Sometimes, you may not want to invest in a top-quality machine if you’re only going to use it occasionally. Determine what are your company’s real need of screen printing machines.

Refer online reviews

Online reviews of screen printing machinery can help you to make a better judgement on which machine to buy by seeing what other users think. Ask for testimonials or case studies (4-5 years old user) from machine manufacturer.

Hands-on Experience

This could be useful parameter to determine whether it’s the right machine for you or not, giving you a better idea of how user-friendly the machine is. Another option could be to get demo of the product so that you can see how well it performs

Delivery method

When getting a machine delivered, it’s important to consider the delivery process. Large machines may need to be delivered in parts (FASDRY, Auto Take off) – you may have the option to assemble them yourself or pay extra for professionals to do it for you. With smaller machines it’s possible you may be able to install them yourself.

Installation and training

You may also want to put your employees through training –of installation, maintenance and operations of screen printing machine. Another option is to hire new staff that are already trained to use this equipment.

Put in place health and safety measures

Health and safety are important when handling machinery. Training your staff is also important and could prevent accidents. Invest in all the health and safety measures possible to make your employees safe and protect your company legally.

Get insured

It’s worth getting your machinery insured just in case theft occurs. Industrial machinery insurance may also be able to protect against damage caused by fire or natural disaster.

Maintenance

Most of UNITECH machines can be maintained easily. Make sure that you know the maintenance requirement to keep any machines in good condition. Alternatively, you may have the know-how to maintain it yourself. Many of UNITECH machinery may simply need to be cleaned and topped up with fluids and come with its own diagnostics SDS for helping to spot faults.

Above criteria are the ready recknor for you to do your need analysis and select the correct one needed for your business.