Get the best out of you ”

Predicting print results not only increase comfort level of the print shops but also give them competitive advantage. Do you really have that advantage? Can you predict print results before screen printing?

UNITECH EVENCOAT - AUTOMATIC EMULSION COATER IS DEPENDABLE

By DEPENDABLE, we mean their EOM (percentage of emulsion over mesh) is more consistent.

No matter who uses the machine it will consistently apply emulsion the same every time.

More pressure or more speed equals lower EOM percentages or less emulsion on the mesh. Less pressure or less speed increases EOM.

What is EOM & Why it is so important?

EOM - means emulsion over mesh, it derives the print quality. Perfect EOM creates a layer with the substrate to print sharp dots and reduces dot gain as well as creating sharp edges for spot color printing. For water base and discharge the EOM is crucial to the durability of the stencil. if the exposure timing will differ according to EOM thus, we must take care of EOM.

It should be consistent like our exposing time period. If we fail to coat screens evenly, we will be producing screens underexposed and will breakdown sooner or overexposed stencils where print details will be lost. Moreover, uneven coating leads to uneven drying of stencils leads to uneven expose which in turned to uneven ink deposition of inks while printing

It's very simple? The key is adjusting coater pressure and speed to achieve the desired EOM.

Coating Pressure, speed, and the type of emulsion used need to be balanced to achieve the desired EOM. When changing to a new emulsion the EOM should be measured again. Coating pressure and speed adjusted to meet the target EOM percentage.

EVENCOAT can be programmed with different coating recipes. It all depends on the mesh, the coater settings, and the flow characteristic of the emulsion.

Don't take Chances!

With Correct Coating Angle, EVENCOAT coats slowly & evenly to keep air bubbles away from forming. Hand coaters ignore this and incorrect Coating Angle, Unpredictable EOM, under or over exposure, and lots of pinholes. In manual process EOM can vary by 20% - 100% from screen to screen so will be the quality of exposure causing breakdown on press.

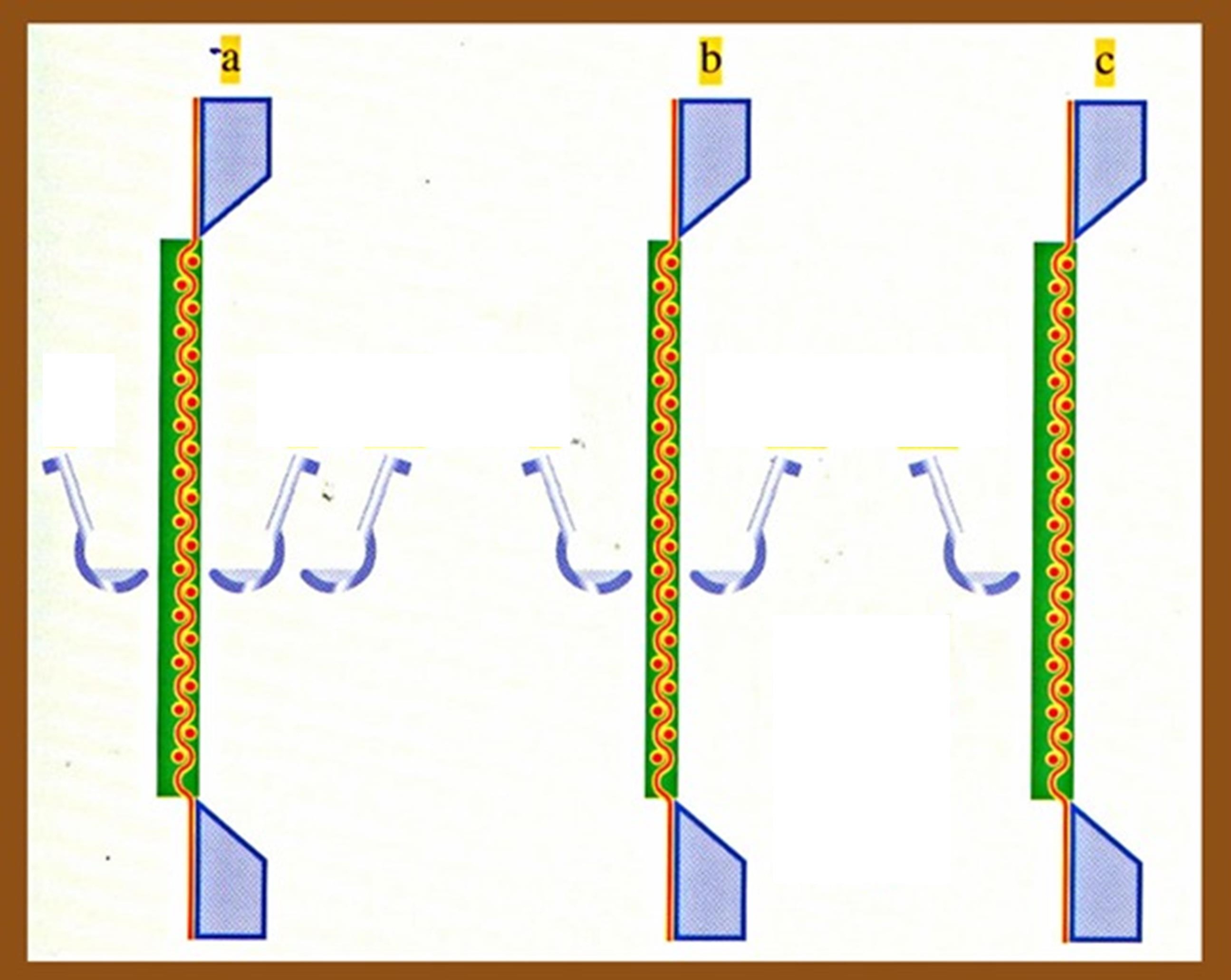

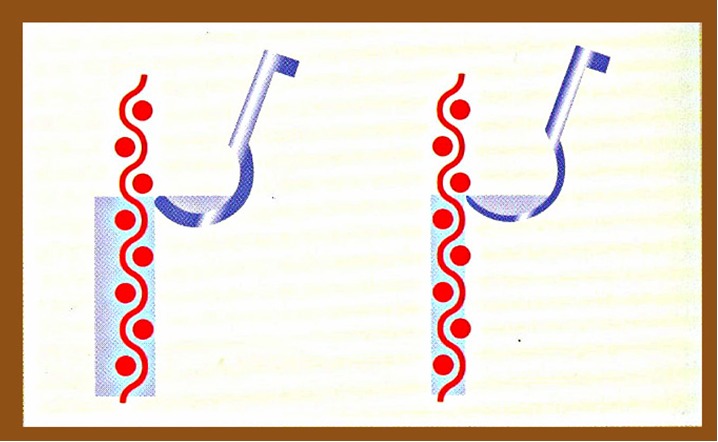

a) Conventional wet on wet coating technique

b) & c) wet on dry coating technique to combine a low & uniform surface profile.

A minimum of emulsion builds up is essential for optimum print sharpness.